Understanding the Warehouse Management System

A comprehensive guide to understanding Warehouse Management Systems (WMS). This in-depth resource explores the various types, key features, historical evolution, benefits, and the future of WMS technology.

In today’s fast-paced commercial landscape, warehouses serve as the lifeblood of trade and commerce. With supply chains growing increasingly intricate, efficient warehouse management has become a critical competitive advantage for businesses. A Warehouse Management System (WMS) plays a pivotal role by delivering detailed visibility and robust reporting capabilities that streamline warehousing operations on a large scale.

In the realm of logistics, a WMS has evolved into an indispensable asset, enabling businesses to maintain agile operations. Features like real-time data analytics, RFID integration, and cloud-based scalability have transformed it from a mere tool into a strategic powerhouse for modern enterprises.

What is a Warehouse Management System?

A Warehouse Management System (WMS) is a sophisticated digital solution designed to optimize warehouse operations, from inventory tracking to order fulfillment. Acting as a centralized control hub, it ensures goods are efficiently stored, managed, and dispatched to meet operational demands seamlessly.

As global trade becomes increasingly complex and customer expectations for faster deliveries grow, businesses require a dynamic, scalable tool capable of adapting to ever-changing market needs in real time. A WMS provides this adaptability, serving as the backbone of efficient logistics operations.

Today, Warehouse Management Systems are indispensable across the supply chain, playing a vital role in supporting dynamic fulfillment operations across industries. Below is a high-level breakdown of how WMS benefits different sectors:

- E-commerce/Direct-to-Consumer (DTC):

E-commerce platforms and DTC brands rely on robust systems to manage extensive inventories and deliver orders swiftly. A WMS enables precise product tracking, optimizes storage utilization, and accelerates order processing to meet high customer expectations. - Third-Party Logistics (3PL):

3PL providers, tasked with managing storage and transportation for multiple clients, depend on WMS to enhance operational efficiency and transparency. Real-time insights, optimized cargo handling, and reduced overheads allow them to deliver superior service to their clients. - Distribution:

Distributors bridge the gap between manufacturers and retailers, managing diverse inventories and fluctuating demands. A WMS enhances route optimization, ensures timely deliveries, and automates routine tasks to streamline operations. - Manufacturing:

Manufacturers leverage WMS to oversee raw material flow, monitor finished goods storage, and maintain a consistent supply chain. These systems minimize downtime, maximize productivity, and deliver a higher return on investment.

In today’s omnichannel environment, businesses must seamlessly manage both online and offline channels. The most advanced WMS solutions address these complexities by providing a unified view of inventory, automating order routing, and delivering actionable insights for smarter decision-making. Furthermore, as business models evolve—from subscription services to on-demand deliveries—a WMS ensures businesses remain agile, adaptable, and laser-focused on customer satisfaction.

How Does a Warehouse Management System Benefit the Warehouse?

As business demands continue to evolve, organizations are encountering challenges that require more robust and adaptive solutions.

When warehouses struggle with inefficiencies caused by manual processes, rising operational costs, or difficulties in managing inventory, these are clear indicators that a Warehouse Management System (WMS) is the only solution. Beyond addressing inefficiencies, a WMS becomes indispensable for businesses aiming to embrace digitization, integrate multiple commercial systems, and strengthen customer and supplier relationships.

Warehouse Management Systems empower supply chains to scale seamlessly, enabling businesses to grow without being burdened by increasing overhead costs. They provide a dynamic framework that not only supports operational efficiency but also drives long-term scalability.

For companies seeking to scale and unlock growth opportunities, a WMS offers transformative benefits that redefine warehouse operations and set the foundation for sustainable success.

Benefits of Warehouse Management System (WMS)

Digitization

A Warehouse Management System (WMS) revolutionizes warehousing by transitioning operations into a fully digital ecosystem. Through the integration of RFID tagging, barcodes, and sensors, warehouses gain real-time visibility into inventory and fulfillment processes, accessible 24/7.

Digitization enhances accuracy and traceability, ensuring that every product within the warehouse is accounted for. With these real-time insights, businesses can forecast demand with precision and implement just-in-time strategies to optimize inventory management. This level of control proves especially critical in scenarios such as product recalls, where rapid and accurate traceability is essential.

Elimination of Manual Processes

Traditional warehouse operations relied heavily on manual tasks, often involving pen-and-paper methods and spreadsheet-based workflows, which left significant room for human error.

A Warehouse Management System (WMS) eliminates these inefficiencies by automating critical tasks such as generating picklists, synchronizing order and inventory data, and removing the need for manual data entry. By seamlessly integrating with other systems, a WMS ensures that inventory and order information stays accurate and up-to-date.

The enhanced speed of data validation and inventory consolidation not only reduces errors but also allows for faster resolution of fulfillment issues, improving overall efficiency and customer satisfaction.

Cost Reduction

A strategically implemented Warehouse Management System (WMS) addresses challenges across key areas such as picking, packing, inventory management, and shipping. These process optimizations not only improve operational efficiency but also contribute directly and indirectly to significant cost savings.

By maintaining optimal inventory levels and automating tasks like liquidation, a WMS helps businesses minimize overheads and maximize space utilization. Features such as identifying perishable or date-sensitive stock ensure prioritized picking, reducing waste and enhancing efficiency.

Warehouse space—one of the largest operational expenses—can also be optimized with a WMS. In 2022, average warehouse space utilization was reported at 85.6%. With a WMS, businesses can unlock even greater efficiency by leveraging vertical space, adopting smart layout designs, utilizing advanced pallet racking systems, and conducting regular audits. This holistic approach leads to reduced costs across the entire fulfillment pipeline.

Connected Commerce

Leading Warehouse Management Systems (WMS) serve as the central hub in a seamlessly interconnected ecosystem of integrated tools, including Transport Management Systems (TMS), Enterprise Resource Planning (ERP), sales channels, and accounting platforms. These integrations enable a two-way exchange of information, providing warehouse managers with a unified, real-time view of operations while eliminating data silos.

A connected commerce approach is vital for adapting to rising order volumes and capturing new market opportunities without interruptions. By fostering collaboration across systems, a WMS ensures operational continuity and empowers businesses to stay agile in an ever-evolving market.

Strengthened Customer and Supplier Relations

A Warehouse Management System (WMS) enhances communication by enabling real-time responsiveness to customer inquiries. Faster response times, precise delivery estimates, and rapid issue resolution are critical to building trust in a warehouse’s operational capabilities. This consistent engagement fosters higher customer satisfaction, loyalty, and a stronger reputation in the market.

Beyond improved order visibility, a WMS empowers warehouses to handle increased order volumes while meeting tight delivery deadlines. Advanced features support personalized shopping experiences for end consumers through customized bundles, labeling, and kitting options, adding a layer of value to the service.

Additionally, an intelligent WMS doubles as a robust reporting tool, offering detailed insights into the customer purchasing journey. Businesses can harness these insights to refine operations and further elevate the overall customer experience.

Evolution of Warehouse Management Systems

Warehousing dates back to ancient Egypt, with the term “warehouse” first officially recorded in 14th-century Great Britain. Over time, warehouses have transformed from simple storage facilities, like centralized storehouses and guildrooms, into highly sophisticated hubs of modern logistics. This evolution has been shaped by significant advancements in transportation, global trade, and digital technology, each adding new layers of complexity to warehousing operations and driving the need for more efficient management solutions.

From Simple Storage to Digitized Systems

The late 19th and early 20th centuries, during the Second Industrial Revolution, laid the groundwork for the digitization of warehouse management. However, a significant leap forward came in the 1960s with the development of the Automated Storage and Retrieval System (AS/RS) by Demag (now Dematic).

First deployed in a German book club warehouse, the AS/RS represented a pioneering integration of robotics and software. This innovation streamlined logistics processes, enhanced storage accessibility, and maximized space utilization. By marrying technology with traditional warehousing, it ushered in a new era of efficiency, marking the true beginning of the digital transformation in warehouse management.

The Birth of the Modern WMS

The 1970s marked a turning point in warehouse management, fueled by rapid advancements in computer technology and mainframe applications. During this transformative decade, the first warehouse management systems (WMS) emerged, setting the foundation for modern supply chain operations.

Walmart opened its first distribution center in 1971, signaling a shift towards more centralized and efficient inventory practices. Around the same time, linear barcodes began gaining traction as a universal standard for retail and grocery items. The first recorded use of a UPC barcode scanner was in 1974, on a packet of Wrigley’s chewing gum. Interestingly, the concept of barcoding has roots in Morse code, with its initial idea conceived by Norman Joseph Woodland and Bernard Silver in the 1940s. Before barcodes became a staple, warehousing operations relied heavily on manual data entry—a process that was both time-intensive and error-prone. The introduction of barcoding revolutionized these operations, enabling faster and more accurate data collection.

That same year, J.C. Penney spearheaded a groundbreaking advancement in warehouse management by developing and deploying the first real-time WMS. This system was a game-changer, leveraging barcoding technology to simplify inventory tracking and optimize supply chain processes. This innovation not only transformed warehouse operations but also paved the way for the sophisticated, tech-driven systems we rely on today.

WMS Proliferation in the 1990s

The 1990s witnessed the proliferation of warehouse management systems (WMS) as global trade surged and supply chains became more intricate. Industry leaders like JDA, Manugistics, and Red Prairie built upon the early examples of WMS to introduce their own proprietary systems, designed to meet the evolving demands of rapidly expanding warehouses and distribution centers.

This era marked a turning point where scalability and efficiency became paramount. With globalization driving trade to unprecedented levels, warehouses faced increasing pressure to streamline operations, optimize space utilization, and manage higher volumes of goods. WMS solutions were instrumental in addressing these challenges, enabling businesses to adapt to the complexities of international logistics.

The focus during this period was not just on automating existing processes but also on integrating new technologies to enhance visibility, accuracy, and overall supply chain performance. This laid the groundwork for the sophisticated, interconnected systems that define modern warehouse management.

Modern Innovations

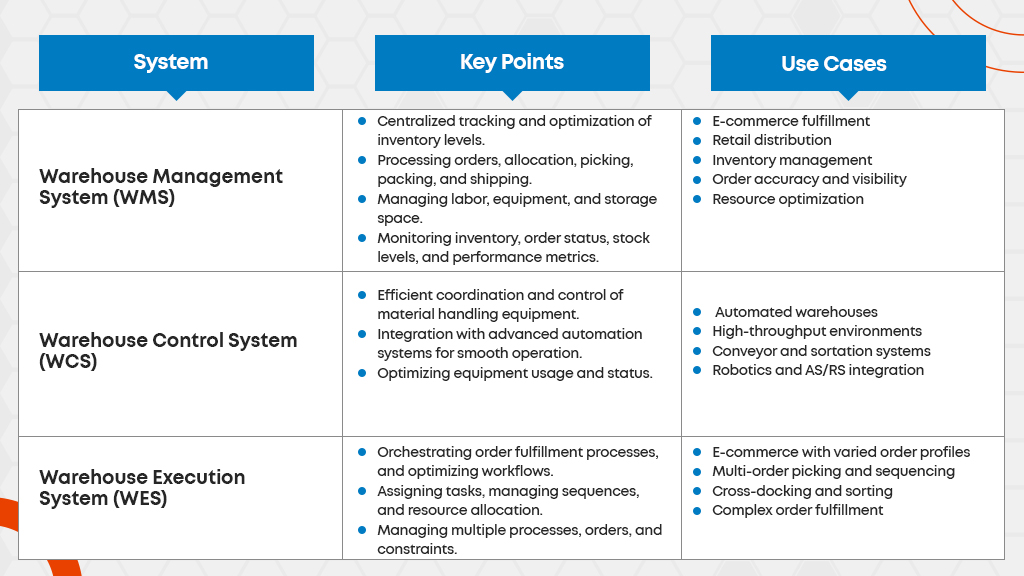

By the mid-1990s, the supply chain industry had evolved into a competitive and fast-paced arena, with growing demands for enhanced visibility and control to manage increasingly complex warehousing operations. This period saw the emergence of the warehouse control system (WCS) as a foundational module, enabling better coordination of equipment automation, inventory control, order management, process execution, and task processing.

These advancements paved the way for the second generation of WMS, introducing transformative features like cross-docking, RFID integration, and automated task creation. Cross-docking streamlined the flow of goods by minimizing storage time, while RFID technology enabled real-time tracking of inventory, significantly improving accuracy and efficiency. Automated task creation further optimized workflows, reducing the dependency on manual intervention and boosting operational agility.

Technological leaps in software development, networking, and telecommunications enabled seamless data integration across disparate systems. This integration marked a paradigm shift, as warehouse management systems in logistics significantly reduced manual labor while driving optimized labor utilization, resulting in faster order fulfillment processes.

With these innovations, businesses gained the capability to scale operations effortlessly, adapt to market fluctuations, and respond to customer demands with greater speed and precision, setting the stage for the dynamic, technology-driven warehousing solutions of today.

Cloud: The Modern Paradigm Shift

Cloud-based architecture has transformed warehouse management systems in logistics. Unlike traditional client-server systems, cloud solutions provide enhanced control, security, and transparency, with real-time access from anywhere. These systems are resource-efficient, cost-effective, and particularly suited for small to medium-sized warehouses.

The pay-as-you-use model eliminates the need for significant upfront investments in expensive server infrastructure. Additionally, a cloud-based warehouse management system scales seamlessly with business growth, reducing operating and capital expenses while delivering better ROI.

Looking Ahead

As e-commerce continues to flourish and consumer expectations rise, the importance of warehouse management systems is increasingly evident. Businesses of all sizes now rely on adaptable and efficient warehousing solutions, emphasizing the growing role of advanced WMS in modern commerce.

Reflecting on the journey of warehouse digitization, it’s remarkable to see how much progress has been made. With the shift towards online shopping, technologies such as AI-powered optimization, robotics, and RPA are ushering in a new chapter in warehouse management, shaping the future of the industry.

Key Features of Warehouse Management Systems

Warehouse management systems go beyond basic inventory management, streamlining processes from receiving to shipping. Modern WMS solutions provide a connected, adaptable experience within and across warehouses, integrating automation seamlessly while eliminating the need for manual, spreadsheet-based workflows.

These systems enable synchronized operations, automate repetitive tasks, and adapt to evolving warehousing demands. Below are the key features that drive efficiency, accuracy, and seamless order fulfillment, while fostering connectivity across the supply chain.

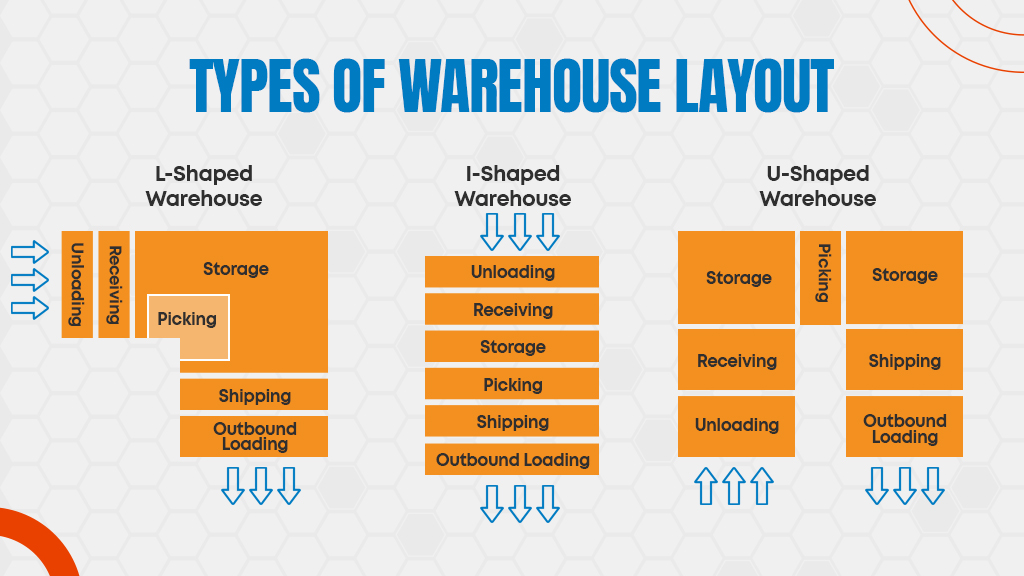

Space and Layout Management

While expanding the physical size of a warehouse requires significant investment, optimizing the available space is achievable with the right tools.

A warehouse management system (WMS) enables precise configuration of storage areas, including bin storage, pallet storage, and buffer zones. By leveraging CAD software for layout design, gaining insights into optimal space utilization, and using IoT sensors for real-time space monitoring, businesses can extract maximum value from their warehouse space.

Efficient space management not only enhances storage capacity but also improves the flow of goods and ensures products are easily accessible and retrievable.

Inventory Optimization

A warehouse management system (WMS) in logistics provides real-time visibility into inventory and stock levels, from inbound shipments to storage, ensuring seamless management. Below is an overview of how a WMS optimizes inventory:

- A WMS offers continuous monitoring of stock levels, ensuring inventory is stored appropriately while considering factors like perishability and priority.

- By utilizing artificial intelligence, advanced WMS platforms predict future inventory needs. This forecasting helps warehouses prepare for demand fluctuations, reducing the risks of overstocking or running out of essential items.

- Analytics-driven insights help maintain optimal stock levels, preventing costly overstocking or stock-outs while ensuring product availability to meet customer demands, enhancing satisfaction.

- When overstocking occurs, a WMS suggests effective liquidation strategies to minimize losses. For instance, Avery Dennison Corp estimates $163 billion in inventory is discarded annually due to expiry or overproduction.

- For perishable goods, a WMS ensures proper tracking and timely dispatch, reducing waste and improving order fill rates.

Inventory optimization is crucial for efficient tracking of perishable items and boosting order fulfillment rates. With rules-based logic tailored to your warehouse, you can ensure timely, accurate deliveries to end consumers.

Order Management

A WMS consolidates orders from multiple sales channels while applying tailored fulfillment protocols based on the order’s source and type, ensuring consistency and precision. Integration with Order Management Systems (OMS), EDI for order synchronization, billing, and automated sorting systems enables seamless consolidation of billables through a built-in rules engine, ensuring accuracy and transparency.

Efficient order management minimizes processing time, reduces errors, and guarantees on-time delivery to customers. Additionally, maintaining order history allows businesses to benchmark product performance and track efficiency metrics for continuous improvement.

Inbound and Outbound Management

Top-tier warehouse management systems seamlessly coordinate the complete product lifecycle within a warehouse, from receiving to shipping. During the receiving phase, the WMS automates tasks such as unloading, generating warehouse labels, and directing workers to designated storage locations. It enhances the putaway process by recommending optimal storage areas based on product characteristics and available space.

The WMS integrates with automated guided vehicles (AGVs) for material handling, conveyor systems for efficient transfers, and barcoding systems for precise tracking. This streamlined approach boosts throughput, minimizes errors, and reduces lead times.

For outbound operations, advanced recommendation engines determine the best picking strategies, considering order specifics and warehouse layouts. Intelligent routing guides pickers along the most efficient paths, ensuring accuracy and speed. Additionally, the system integrates with transportation management systems and carriers to facilitate rate shopping and shipping coordination, further optimizing logistics.

Control Tower

A warehouse management system (WMS) serves as a control tower, offering a comprehensive 360-degree view of all warehouse activities. It enables managers to monitor processes, detect bottlenecks, and resolve exceptions from a centralized point. With the help of advanced analytics platforms, real-time dashboards, and alert systems, warehouse operations can be effectively managed from both a strategic and operational perspective.

A smart WMS (e.g. 3PLNext), considered the best in the industry, combines detailed visibility with powerful reporting and analytics. This integration enhances decision-making, optimizes resource allocation, and accelerates response times, ensuring efficient and effective warehouse management.

Vendor and Customer Management

Modern warehouse management systems facilitate seamless data exchange and communication with both suppliers and customers. They serve as a centralized platform for vendor interactions and order integration. With built-in connectors and enterprise service buses (ESBs), these systems streamline vendor integration, enabling faster onboarding and enhancing the overall partner experience.

Strong vendor and customer relationships are vital for maintaining consistent supply and demand fulfillment. A well-optimized vendor experience often translates into an improved customer experience, particularly in e-commerce. WMS solutions can consolidate orders from multiple sales channels, prioritizing fulfillment based on pre-set rules and criteria.

For end consumers, warehouse management systems offer self-service features to enhance the customer experience. Benefits like expedited delivery timelines, accurate order processing, real-time order tracking, and streamlined returns management drive customer satisfaction and strengthen brand loyalty. Additionally, WMS tools provide a unified platform to address and resolve customer concerns promptly, fostering better relationships with both vendors and customers.

Shipping and Freight Management

A warehouse management system seamlessly integrates with transportation management systems (TMS) to optimize shipping operations. It facilitates rate shopping, ensuring cost-effective carrier selection, and provides end-to-end tracking throughout the delivery process. By leveraging carrier performance analytics, businesses can negotiate better rates and service-level agreements (SLAs), enhancing both cost efficiency and service quality.

Efficient shipping is critical for on-time deliveries, reducing expenses, and fostering strong carrier relationships. Through automation, WMS solutions streamline daily tasks such as billing, packing list generation, and shipment invoice creation, reducing manual effort and errors.

Offering diverse shipping options gives customers the flexibility to choose delivery timelines, schedules, and costs that best suit their needs. Additionally, WMS systems enable real-time package tracking and issue automated notifications to relevant parties in case of delays, ensuring transparency and maintaining customer trust.

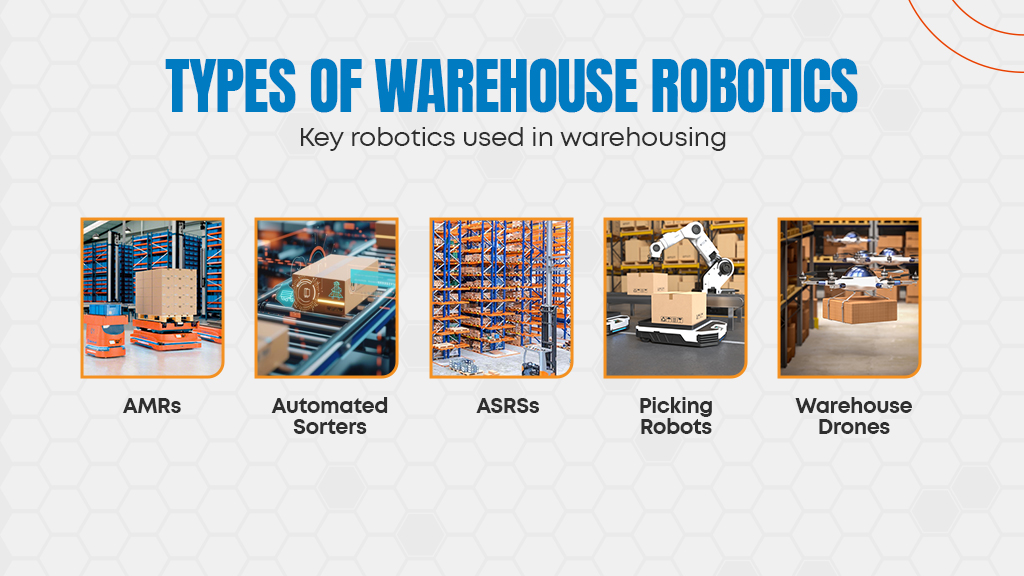

Device and Robotic Control

A warehouse management system serves as a centralized hub for managing and controlling automated devices and robotics, such as autonomous mobile robots (AMRs) and sorter belts. With IoT integration, the WMS enables real-time monitoring of device performance, tracks equipment health, and schedules preventive maintenance to minimize downtime.

AMRs collaborate with warehouse workers to reduce errors and significantly enhance productivity. Robotics and automated systems, including conveyor belts, automated storage and retrieval systems (AS/RS), and drones, not only optimize operations but also create a safer work environment. These advancements help reduce worker fatigue, prevent burnout, and lower the risk of workplace accidents, fostering a more efficient and sustainable warehouse ecosystem.

Multi-Warehouse Management

A warehouse management system (WMS) is a vital tool for efficiently managing multi-client and multi-location warehouse operations. By connecting multiple warehouses, it ensures seamless order routing, inventory distribution, and resource allocation, creating a unified and streamlined operation. Here are the key features and capabilities of effective multi-warehouse management:

Managing Multiple Warehouses or a Warehouse Network

- Centralized Management:

A WMS provides a unified platform to manage inventory, workforce, and equipment across various warehouse locations. This centralized control ensures operational consistency and better coordination throughout the network. - Streamlined Processes:

By automating key workflows such as receiving, put-away, picking, and shipping, the WMS reduces manual errors and ensures uniformity across all warehouses.

Centralized and Localized Views Based on User Roles

- Centralized View:

Top-level managers and administrators can monitor the overall warehouse network through a holistic dashboard, tracking inventory levels, workflows, and performance metrics across all locations. - Localized View:

Local managers and supervisors benefit from tailored insights into their specific warehouse operations, enabling them to manage day-to-day activities, resolve issues, and optimize their teams’ performance effectively.

Multi-Warehouse Operations

- Order and Consignment Routing:

The WMS identifies the best warehouse to fulfill an order based on factors like stock availability, proximity to the customer, and shipping costs, ensuring timely and cost-effective deliveries. - Stock Transfers:

To prevent stock-outs, the WMS facilitates inter-warehouse transfers, optimizing inventory rotation and ensuring product availability across all locations. - Synchronized Inventory Management:

Real-time inventory tracking across all warehouses allows for better replenishment decisions, reduced holding costs, and improved stock accuracy.

Performance Analytics

- Key Metrics Tracking:

The WMS tracks vital metrics like order accuracy, fulfillment speed, inventory turnover rates, and equipment utilization to gauge operational efficiency. - Individual Warehouse Performance:

Insights into the productivity and accuracy of each warehouse help managers identify bottlenecks and implement improvements. - Overall Network Analysis:

Data aggregation across all warehouses provides a comprehensive overview of the entire network, aiding in strategic planning, forecasting, and long-term decision-making.

Benefits of Multi-Warehouse Management

An effective WMS simplifies complex operations, enhances visibility, and ensures seamless integration across multiple locations, helping businesses meet customer demands efficiently while optimizing resources and reducing costs.

3PL Warehousing

A 3PL warehouse management system (WMS) simplifies the complexities of 3PL warehousing operations by offering tailored integrations and flexible modular designs. It acts as a centralized solution that facilitates real-time data flow in a multi-client setup. These pre-built 3PL integrations are particularly advantageous for e-commerce operations, as they seamlessly connect sales and fulfillment channels with ERP, accounting, TMS, and shipping systems. Additionally, 3PL billing features enhance invoice accuracy and transparency by ensuring all billables are correctly recorded.

Different warehouse management systems with multi-client capabilities enable structured management of client-specific tasks. Furthermore, performance metrics and reporting tools offer detailed insights into each client’s supply chain performance.

This cohesive approach empowers 3PL providers to manage diverse client needs effectively, optimize their operations, and deliver high service standards within a single integrated framework.

Dock Scheduling and Yard Management

Warehouse management systems incorporate features that simplify dock scheduling and improve yard management, ensuring seamless inbound and outbound operations. These systems handle tasks such as coordinating truck appointments and optimizing resource allocation, leading to enhanced efficiency and increased overall warehouse productivity.

Analytics and Reporting

A smart warehouse management system (WMS) transforms the way data is utilized to drive decision-making. By leveraging automated data collection, seamless integration with analytics platforms, and dynamic visual reporting, warehouses can uncover actionable insights to enhance operations.

The system enables the generation of reports at the ERP level, offering a comprehensive view of critical metrics such as on-time shipping, inventory accuracy, distribution costs, and order fill rates. These reports are visually engaging and accessible to stakeholders, facilitating strategic planning and improved operational performance.

With real-time inventory tracking, warehouses can proactively manage stock levels, ensuring timely restocking and efficient resource utilization. Workflow management tools provide a detailed analysis of warehouse activities, helping to identify inefficiencies and address anomalies. Additionally, many WMS vendors support multi-location tracking, accommodate various languages, tax structures, and currencies, making them suitable for global operations.

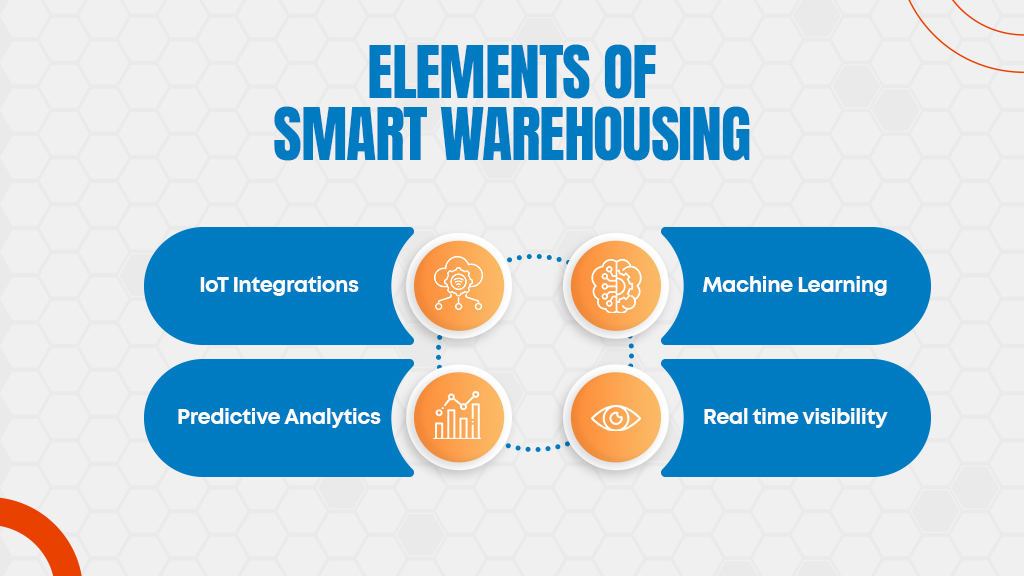

Role of Warehouse Management System in Smart Warehousing

Smart warehousing represents the next evolution in warehouse management, driven by technology and innovation. A recent survey highlights that over 40% of businesses are prioritizing supply chain transformation as part of their strategic goals.

Key enablers of this transformation include IoT integrations, machine learning, advanced process optimization, predictive analytics, and real-time visibility. Together, these technologies enhance warehouse efficiency, improve accuracy, and empower better decision-making. By integrating these capabilities, a WMS fosters a seamless, agile warehousing ecosystem that meets the demands of modern supply chains.

IoT Integrations and Machine Learning

Integrating Warehouse Management Systems (WMS) with Internet of Things (IoT) is transforming smart warehousing by providing real-time tracking of assets, products, and workforce activities. IoT applications in modern warehouses are extensive — sensors monitor asset movement, environmental conditions, worker locations, energy usage, and equipment performance, ensuring operational transparency and efficiency.

At the same time, machine learning leverages data from various sources to identify patterns and make predictive adjustments. It forecasts demand, optimizes picking routes, and allocates resources intelligently, effectively reducing bottlenecks and enhancing overall process efficiency.

Predictive Analytics and Real-time Visibility

Smart warehouses leverage predictive analytics to anticipate inventory demands, workforce needs, and potential disruptions by analyzing historical trends alongside real-time data. With comprehensive visibility across the supply chain—including inventory levels, order statuses, equipment performance, and employee productivity—smart warehouse management systems create digital simulations to test scenarios and improve decision-making.

These predictive insights enable warehouse managers to proactively resolve challenges, seize opportunities, and ensure seamless operations, all while maintaining peak efficiency and minimizing downtime.

Next Steps

The rapid expansion of trade and commerce has put immense pressure on supply chain operations. Modern warehouses must rise to the challenge by adopting the right technology or risk falling behind. Today, warehouse management systems embody cutting-edge automation, robotics, and process optimization, making them indispensable for managing complex warehouse operations.

However, even the most advanced warehouse management system is only as effective as its alignment with your unique business needs. Success lies in creating a harmonious balance where technology integrates seamlessly with people and processes to scale warehouse operations efficiently.

At 3PLNext, we understand the unique demands of warehousing and specialize in tailoring solutions to meet your operational goals. Let us help you optimize your warehouse operations and unlock your business’s full potential.

Leave a Reply