Cloud-Based Inventory Management Systems: How Modern Architecture Transforms Fulfillment

Fulfillment has fundamentally changed.

Modern operations are no longer single-warehouse, single-channel environments. Today’s 3PLs and high-volume brands operate across multiple facilities, marketplaces, automation systems, and geographies, all while customers expect real-time tracking and near-instant delivery.

To support this complexity, technology must evolve.

This is where cloud-based inventory management systems redefine what’s possible. Not simply as a hosting alternative, but as a modern architectural framework that improves speed, visibility, scalability, and automation readiness across the entire fulfillment ecosystem.

What Cloud-Based Inventory Management Systems Are, And How They Work

A cloud-based inventory management system is a stock management platform hosted on secure remote infrastructure rather than on local servers. It operates entirely online, giving teams secure access from anywhere while maintaining centralized control.

Here’s how modern cloud systems function:

- Real-Time Data Synchronization

Every operational event, receiving, picking, packing, cycle counting, shipping, updates inventory levels instantly across the platform.

When a warehouse associate scans a SKU during picking, stock levels are automatically adjusted across:

- All sales channels

- All warehouse locations

- All client dashboards

- All connected integrations

This creates a single, live source of truth, eliminating delayed batch updates and reducing costly allocation errors.

- Centralized Inventory Visibility

Cloud-based systems provide one unified dashboard for all inventory activity.

Whether stock is stored in:

- A single distribution center

- Multiple domestic facilities

- International warehouses

- Third-party partner locations

Everything is visible in one interface.

Executives, operations managers, and warehouse teams all operate from the same real-time data environment.

- Multi-Location & Intelligent Order Routing

Modern cloud systems automatically attribute inventory to specific facilities and enable rule-based routing.

Orders can be intelligently assigned based on:

- Stock availability

- Geographic proximity

- Client SLAs

- Shipping cost optimization

This reduces fulfillment time and shipping expense while improving customer experience.

Why Businesses Are Moving Away from On-Premises Systems

On-premises systems were a major upgrade from manual inventory tracking. However, they struggle to keep pace with modern fulfillment complexity.

Here’s why businesses are transitioning to cloud-native platforms:

Costly Maintenance

On-premise systems require:

- Physical server infrastructure

- Dedicated IT teams

- Manual upgrades

- Ongoing security management

As operations scale, so do infrastructure costs. Cloud systems eliminate server maintenance and reduce IT overhead.

Slow Upgrade Cycles

Legacy systems often require scheduled downtime for updates.

This means:

- Disrupted operations

- Delayed feature releases

- Operating on outdated software

Cloud-native platforms deploy continuous updates seamlessly, without interrupting operations.

Limited Scalability

Scaling an on-premise environment requires:

- Purchasing new hardware

- Installing additional licenses

- Planning infrastructure expansion

This creates capital expenditure before growth even begins.

Cloud systems, by contrast, scale elastically, expanding or contracting based on real-time demand.

Barriers to Automation Integration

Modern warehouse automation, including AMRs, ASRS, robotic picking, and conveyor systems, depends on real-time API communication.

Traditional systems often require custom development to integrate automation technologies. Cloud-native platforms are built with open APIs, enabling seamless ecosystem connectivity.

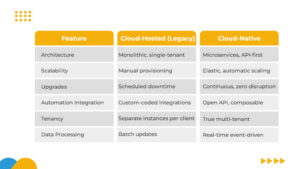

Cloud-Hosted vs. Cloud-Native: Not All Cloud Systems Are Equal

Many vendors claim to offer “cloud-based” software, but there’s a critical distinction between cloud-hosted and cloud-native systems.

Cloud-Hosted Systems

These are legacy on-premise applications moved to cloud servers (“lift and shift”).

The infrastructure changes, but the architecture does not.

Cloud-Native Systems

Built from the ground up for cloud environments, using:

- Microservices architecture

- API-first frameworks

- Serverless computing

- True multi-tenancy

Here’s how they compare:

| Feature | Cloud-Hosted (Legacy) | Cloud-Native |

| Architecture | Monolithic, single-tenant | Microservices, API-first |

| Scalability | Manual provisioning | Elastic, automatic scaling |

| Upgrades | Scheduled downtime | Continuous, zero disruption |

| Automation Integration | Custom-coded integrations | Open API, composable |

| Tenancy | Separate instances per client | True multi-tenant |

| Data Processing | Batch updates | Real-time event-driven |

The architectural foundation determines how agile your fulfillment operation can become.

How Modern Cloud Architecture Improves Speed, Visibility & Scalability

Real-Time Operational Visibility

A cloud-native platform maintains a centralized data environment where every transaction updates instantly.

No lag.

No outdated reports.

No fragmented data silos.

From warehouse floor to executive dashboard, everyone works from the same live dataset.

High-Speed Order Processing

Event-driven architecture allows systems to process order routing, inventory allocation, and workflow automation in milliseconds.

This improves:

- Order fulfillment cycle time

- Picking accuracy

- Shipping speed

- Customer satisfaction

Elastic, Instant Scalability

Peak seasons like Black Friday, Ramadan sales, or promotional campaigns generate massive order spikes.

Cloud-native platforms automatically allocate additional computing resources during high-demand periods, and scale back once demand normalizes.

You pay for usage, not idle infrastructure.

Automation & Ecosystem Readiness

Modern fulfillment is interconnected.

Cloud-native systems integrate seamlessly with:

- Ecommerce platforms (Shopify, Amazon, WooCommerce)

- Shipping carriers (UPS, FedEx, Canada Post, regional carriers)

- ERP systems

- Robotics and automation providers

This creates a unified fulfillment ecosystem instead of disconnected software layers.

Solving Real Fulfillment Challenges with Cloud-Native Inventory Management

Multi-Warehouse Inventory Accuracy

Managing accurate inventory across multiple facilities is one of the biggest operational challenges for 3PLs and growing brands.

A cloud-native platform like 3PLNext resolves this through:

- Continuous real-time synchronization

- Unified dashboards

- Intelligent allocation logic

- Automated stock adjustments

This prevents:

- Double allocation

- Overselling

- Mis-picks

- Cross-location discrepancies

Multi-Channel Synchronization

Inventory levels automatically update across:

- Marketplaces

- Direct-to-consumer storefronts

- Wholesale portals

- EDI connections

This ensures consistent stock accuracy across every sales channel.

Automation Integration

Cloud-native platforms provide the responsiveness required to coordinate robotic systems, automated sortation, and warehouse orchestration tools, adjusting workflows dynamically as conditions change.

High-Volume, Multi-Client 3PL Management

For 3PL operators, complexity increases exponentially with each new client.

A true cloud-native architecture enables:

- Segmented inventory rules per client

- Custom billing logic

- Separate reporting dashboards

- Controlled user permissions

- Multi-client workflows in one instance

3PLNext is designed with this multi-client environment in mind, providing scalable infrastructure without requiring separate system instances per customer.

The Strategic Advantage of Moving to Cloud-Native

Migrating to cloud-native inventory management isn’t just a technical upgrade.

It’s an operational transformation.

With a modern cloud architecture, businesses gain:

- Real-time decision-making capability

- Faster fulfillment cycles

- Reduced IT overhead

- Seamless scalability

- Automation readiness

- Future-proof infrastructure

In a fulfillment landscape defined by speed and complexity, architectural agility becomes a competitive advantage.

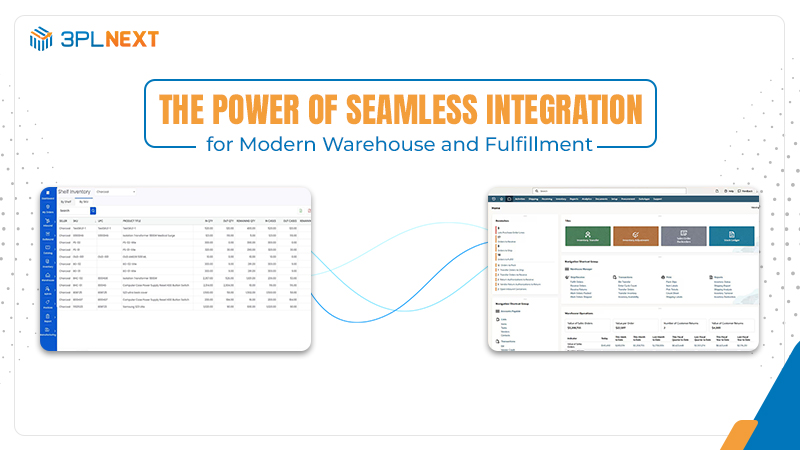

Modernize Your Fulfillment with 3PLNext

3PLNext combines:

- Intelligent inventory management

- Real-time warehouse execution

- Multi-client architecture

- Automation orchestration

- API-driven ecosystem connectivity

All built on modern cloud-native infrastructure engineered specifically for 3PLs and high-volume fulfillment operations.

If you’re ready to move beyond legacy limitations and build a fulfillment operation designed for the future, it’s time to modernize.

Request a demo and experience the difference true cloud-native inventory management can make.

Leave a Reply