Reducing Picker Travel Time with Smart Slotting and Automation: A Strategic Approach to Warehouse Efficiency

In today’s high-speed fulfillment landscape, every step matters — literally. Reducing picker travel time is no longer just a productivity tweak; it’s a vital strategy for increasing operational efficiency, lowering labor costs, and improving overall order accuracy. As ecommerce demand continues to climb and customer expectations become more stringent, fulfillment centers must adopt intelligent automation and optimized warehouse layouts to stay competitive.

From smart inventory placement to robotics and advanced warehouse management systems (WMS), this article explores how forward-thinking strategies can reduce unnecessary movement in your warehouse — enabling your workforce to do more, with less effort.

Why Picker Travel Time Is a Key Performance Factor

Labor represents a significant portion of warehouse operational costs, and much of that labor is consumed in transit — walking between inventory locations to pick, pack, and ship products. Reducing the distance your employees walk isn’t just about speed; it directly correlates to:

- Faster order processing

- Improved worker safety and satisfaction

- Fewer errors

- Increased daily pick volumes

- Lower labor expenditure

Optimizing picker routes starts with warehouse layout design and extends to the use of real-time data and automation technologies. The less your employees walk, the more value they deliver.

Smart Slotting: Making Every Step Count

Smart slotting is the strategic organization of inventory within a warehouse to minimize picker travel and maximize efficiency. Instead of randomly placing products or relying on static shelving assignments, modern fulfillment centers use data-driven strategies to position products based on how — and how often — they move.

Here’s how to reimagine your inventory placement:

High-Frequency SKU Placement

Analyze order data to identify your fastest-moving SKUs and position them near primary picking zones. Products with high turnover should be stored close to packing stations, reducing retrieval time and distance.

Seasonal and Velocity-Based Reorganization

Product demand fluctuates with seasons, trends, and promotions. Dynamically re-slotting inventory according to current sales velocity ensures that pickers aren’t trekking across the warehouse for items that are flying off the shelves.

Zone-Based Slotting

Divide your warehouse into functional picking zones based on product categories or characteristics (e.g., temperature, size, handling needs). Assign pickers to specific zones to minimize movement and improve order accuracy through specialization.

These intelligent slotting practices lead to fewer steps, faster fulfillment, and more efficient use of warehouse space.

Elevating Efficiency with Warehouse Automation

Reducing picker travel isn’t just about layout — it’s also about enabling your workforce with the right tools. Automation solutions are reshaping how goods move through warehouses, reducing manual effort while dramatically increasing output.

Autonomous Mobile Robots (AMRs)

AMRs transport products to and from pickers, minimizing travel and enhancing order throughput. Their flexibility allows them to adapt to changing layouts and dynamic slotting strategies with ease.

Goods-to-Person (G2P) Systems

Instead of sending pickers to retrieve products, G2P systems deliver items directly to workstations. This eliminates travel time altogether and improves accuracy by removing common manual handling errors.

Collaborative Robots (Cobots)

Cobots assist warehouse workers with repetitive or physically demanding tasks, increasing safety and reducing fatigue. They enhance human capabilities without replacing them, fostering a more sustainable and efficient workforce.

While these technologies may require upfront investment, the long-term benefits — including reduced labor costs, faster order fulfillment, and higher employee retention — make automation a strategic imperative.

Strategic Layout and Optimized Picking Methods

The effectiveness of slotting and automation is amplified by a thoughtfully designed warehouse layout and smart picking procedures. Consider these approaches:

Efficient Warehouse Design

Maximize vertical storage, maintain clear aisles, and ensure logical flow between storage and packing areas. Small design choices — like placing packing stations centrally — can significantly reduce walking distance.

Batch and Wave Picking

Group orders with similar SKUs or destinations and pick them simultaneously. Batch and wave picking reduce repetitive travel and improve picking productivity during high-volume periods.

Waveless Picking and Real-Time Prioritization

Unlike wave or batch systems that wait for a batch to accumulate, waveless picking responds in real time to order intake. Dynamic prioritization adjusts task assignments on the fly, directing pickers to the highest-priority orders — optimizing routes and minimizing idle time.

Together, these methods reduce unnecessary steps and keep fulfillment teams focused on efficiency and output.

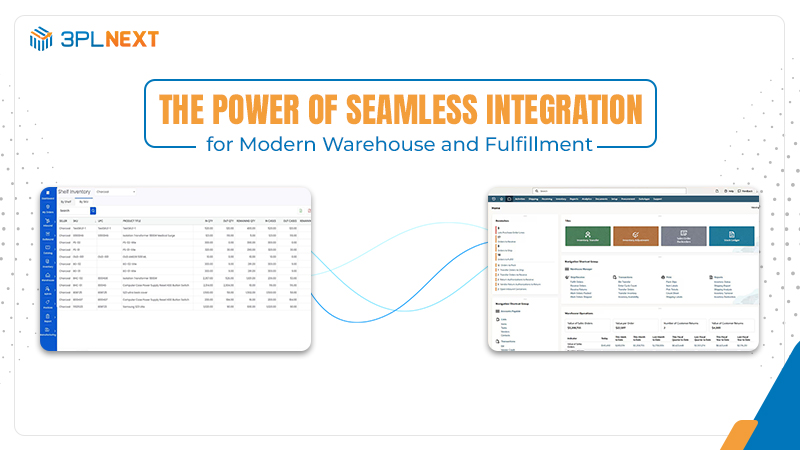

Real-Time Optimization with Advanced WMS Technology

A powerful Warehouse and Fulfillment Management System like 3PLNext is the engine behind all these strategies. By centralizing real-time data, 3PLNext empowers warehouses to:

- Continuously optimize picking paths

- Reslot inventory dynamically based on demand trends

- Track performance metrics like picker productivity and order accuracy

- Forecast demand using predictive analytics

- Automate decision-making across fulfillment operations

With integrated AI and machine learning, 3PLNext makes your warehouse smarter every day — turning data into actionable insights and transforming how you approach every square foot of space.

Work Smarter, Move Faster with 3PLNext

Optimizing your warehouse for reduced picker travel time is about more than just walking less — it’s about working smarter. Combining intelligent slotting, automation, and an advanced WMS like 3PLNext delivers a powerful, future-ready fulfillment infrastructure that scales with your growth.

3PLNext empowers you to:

- Automate repetitive warehouse tasks

- Strategically organize and dynamically manage inventory

- Shorten pick times and increase order throughput

- Improve accuracy, safety, and worker satisfaction

- Create a leaner, more agile fulfillment operation

Ready to minimize waste and maximize performance?

Request a personalized demo of 3PLNext today and discover how reducing picker travel time can unlock your next level of operational efficiency.

Leave a Reply