The Rise of Dark Warehouses: What are they and how do they work?

Dark warehouses may sound eerie, but they are actually an emerging trend. Also referred to as automation or shadow warehouses, these facilities require minimal human intervention. They are revolutionizing the storage, packaging, and distribution of goods. By significantly reducing the need for human involvement, they help operators cut operational costs substantially.

The Concept of Dark Warehouses

Unlike traditional warehouses, which require human involvement in packing and managing inventory, dark warehouses operate in the shadows, using automation technology such as robotics, Automated Guided Vehicles (AGVs), and advanced software systems like Warehouse Management Systems (WMS). This reduces the need for lighting, air conditioners, or heaters, which are installed for human comfort, leading to a decrease in overall costs.

How They Operate

Autonomous warehousing involves the use of fully automated systems that can operate with minimal human intervention. These technologies include robotics, AGVs, and drones.

Dark store operations use highly automated systems, robotics, and AI to effectively manage supply, order processing, and delivery logistics without relying on physically present customers or retail setups.

Now that we know that dark warehouses function using many technologies, lets discuss some common smart warehouse technologies; these include:

- Automated Guided Vehicles (AGVs): These are robots that efficiently transport supplies throughout the warehouse from storage to packing areas.

- Robotic Arms: These are used for picking goods and packing them. They have advanced sensors and machine learning algorithms that enable them to handle a wide range of products quickly.

- Conveyer Systems: They are automated and transport items within the warehouse, streamlining their movement and minimizing the need for human intervention.

- Drones: They are used for supply management, scanning barcodes, and stock checking. They can access hard-to-reach areas quickly and provide real-time data on stock levels, saving time and minimizing the need for manual checking.

- AI and Machine Learning Algorithms: AI algorithms analyze data to predict demand for specific products. This helps manage inventory and organize the warehouse’s layout for maximum efficiency. Machine learning models learn from their past errors and delays to improve the accuracy and reliability of robotic picking.

- Warehouse Management Systems (WMS): Dark warehouse management systems coordinate the activities of all the various automated systems in use in the warehouse and regulate all aspects of its operations, including order processing, receiving, and shipping goods.

Automated Warehouse Management Systems (WMS) utilize robotics, AI, and IoT to optimize storage space and supply management, enhancing accuracy.

- Internet of Things (IoT): IoT devices, such as sensors, are integrated throughout the warehouse to provide real-time tracking of supply, equipment, and weather conditions.

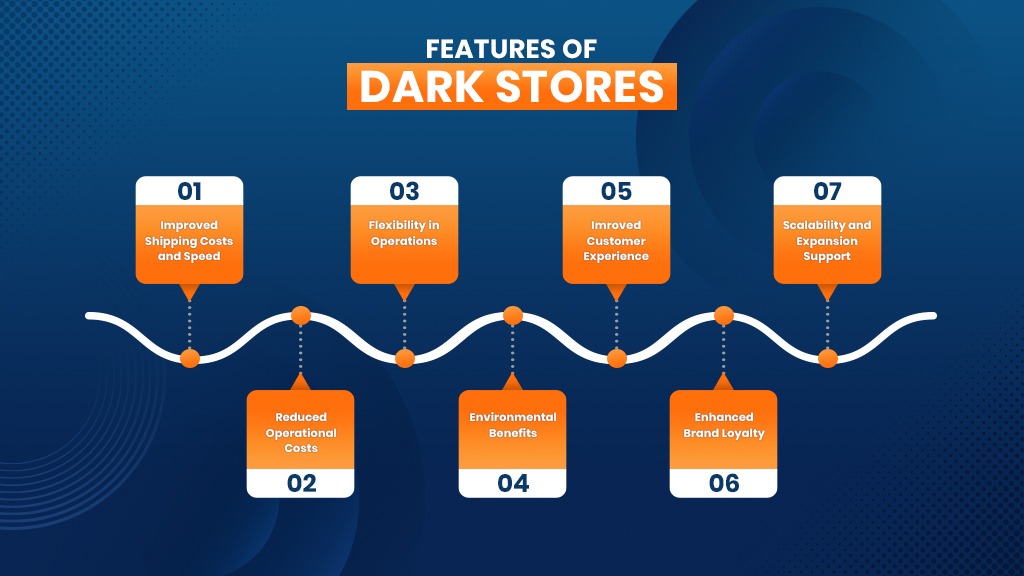

Advantages of Dark Warehouses

Dark warehouses offer multiple benefits, including scalability, enhanced safety, and significant cost savings.

- Scalability: Dark warehouses can easily scale operations based on demand, making them suitable for businesses with unfixed order volumes.

During peak periods, extra robots can handle increased volumes without worrying about the availability of human labor.

- Improved Safety: With fewer workers physically present on site, the risk of workplace injuries has reduced significantly since automated systems and machines can safely handle dangerous tasks, such as dealing with chemical substances or moving extremely heavy loads. This reassurance about safety is a key advantage of dark warehouses.

- Increased Efficiency: Automated systems can operate without breaks for long periods, leading to faster order fulfillment. Moreover, robotics’ precision in warehousing minimizes the chances of errors.

- Cost savings: Dark warehouses significantly reduce electricity costs by eliminating the need for air conditioners, lighting, etc., designed for humans. Additionally, warehouse automation reduces labor costs and other associated expenses, such as training. This financial benefit is a key advantage of dark warehouses, offering a promising return on investment.

Difficulties and Drawbacks

Despite their numerous benefits, dark warehouses have several challenges we must consider to ensure their successful operation.

- High Initial Investment: The greatest and most significant barrier to adopting dark warehouses is the high initial investment required for automation technology. Robotics in warehousing, as well as AI and IoT devices, require substantial expenditure, which can be hard for smaller businesses.

- Maintenance Costs: Automated systems require frequent maintenance to function properly. This maintenance includes both software updates and hardware repairs. These costs add to the maintenance budget, and any downtime during maintenance work can adversely impact warehouse operations.

- Unemployment and employment opportunities: Warehouse Automation has eliminated the jobs of many warehouse workers. However, even though machinery has reduced the need for manual labor, workers who have technical knowledge are still required to maintain the technology used. Companies must invest in employee training programs to help workers handle modern machinery.

- Cyber Security Threats: Dark warehouses use interconnected systems and IoT devices, making them vulnerable to hacking and cyber-attacks. Ensuring the safety of sensitive data is extremely important, so companies must implement cyber security measures for data protection.

By promptly addressing these challenges, companies can enjoy the benefits of dark warehouses, driving innovation in the supply chain industry.

Future of Warehousing

Dark warehouses are the future of warehousing, offering not just scalability and accuracy, but also unparalleled efficiency. By adopting smart warehouse technology like AI, robotics, and IoT, businesses can scale their operations to meet demand and stay relevant in a highly competitive market. Although it is essential to balance technological advancements with investment costs and workforce impact, dark warehousing will surely continue to play a crucial role in this ever-evolving industry.

Leave a Reply