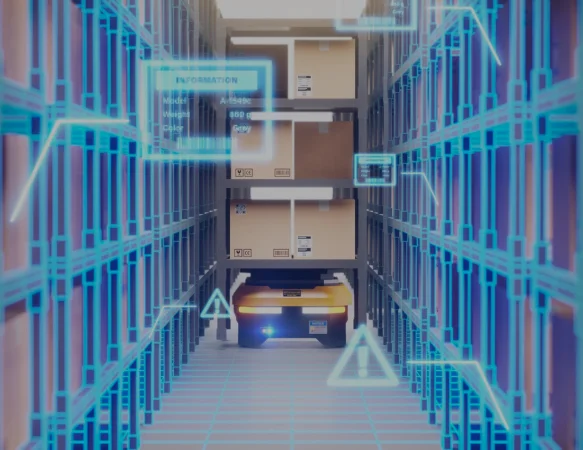

3PLNext is a one-stop solution to all warehouse mishaps hampering your business. Just imagine, how late inventory restock can affect your business. 3PLNext Warehouse Management System Feature List is not only about restocking options, but also about listing, sorting, packing, shipping, and much more. One of the most frequent problems eCommerce fulfillment faces is Warehouse Management.3PLNext effortlessly solves your long-due fulfillment issues and provides the much-needed control to ensure seamless functionality of your business every time.

Learn More

3PLNext brings you all the power-packed Warehouse Management System Features to manage and scale your business at ease. This technology-backed Warehouse Management System (WMS) is an absolute answer to the woes of SMB’s, Enterprise, and eCommerce firms including the Warehouse Owners.

Learn More

The diverse functions of a warehouse management system speak for its capabilities. 3PLNext stands tall as a diverse WMS, which takes care of every in-and-outs of your warehouse. All this increases your efficiency so you can put in efforts to steer your business towards growth.

As simple as it sounds, this warehouse management system manages everything from tracking inventory to Ship Verify. With all this, you eliminate all odds and last-minute issues that could potentially lead to unsatisfied clients.

Learn More

3PLNext Warehouse Management System Functions are not related to a single process, but to the entire warehouse ecosystem. Consequently, that makes your business efficient by saving on your time efforts, and costs. All this comes true with tons of Warehouse Management System Features you get at 3PLNext.

Learn More

3PL software is a solution or system used by 3rd party logistics companies. 3PL management systems are used to manage the entire 3rd party logistics process, including inbound, outbound, sales management, marketing, operations, fulfilment and finance. 3PLs are focused on providing their clients with an efficient logistics solution and 3PL software allows them to automate and streamline their operations, leading to faster fulfilment times and greater efficiency

A Warehouse Management System (WMS) is a software designed to optimize and automate various warehouse operations, including inventory management, order fulfillment, and last mile delivery. It benefits your business by improving efficiency, reducing errors, and enhancing overall productivity within your warehouse operations

Yes, our 3PLNext supports multi-location inventory management, allowing you to efficiently manage inventory across multiple warehouses or distribution centers. This feature helps optimize stock levels, reduce stockouts, and streamline order fulfillment processes

Integrating a WMS into your existing systems is typically straight forward and can be customized to fit your specific business needs. Our team at 3PLNext offers seamless API integration services, ensuring minimal disruption to your operations during implementation

Absolutely! 3PLNext provides real-time visibility into inventory levels and movements throughout your supply chain. You can track stock levels, monitor inbound and outbound shipments, and receive alerts for low inventory levels or discrepancies, enabling proactive decision-making

At 3PLNext, we take data security seriously and follow all regulatory compliance. Our WMS employs industry-leading security measures, including encryption, role-based access control, and regular security audits, to safeguard your sensitive information and ensure compliance with data protection regulations

Yes, our WMS is designed to scale with your business growth. Whether you have a small dark store or a huge warehouse, either you’re a small startup or a large enterprise, our flexible solution can adapt to your evolving needs, supporting increased transaction volumes, additional warehouses, and expanding product lines without compromising performance

Absolutely! Our WMS offers robust automation capabilities to streamline order fulfillment processes, including order picking, packing, and shipping. By automating repetitive tasks and optimizing workflows, you can reduce manual errors, improve order accuracy, and accelerate order processing times

Yes, our WMS supports both barcode scanning and RFID technology for efficient inventory tracking and management. By leveraging these technologies, you can improve inventory accuracy, enhance traceability, and expedite the fulfillment process, leading to greater operational efficiency

The implementation timeline for our WMS depends on various factors, including the size of your business, complexity of your operations, and customization requirements. Our experienced implementation team works closely with you to ensure a smooth and timely deployment, minimizing disruption to your business

We provide comprehensive support and training services to ensure your team can effectively utilize our WMS. From initial onboarding and training sessions to ongoing technical support and system updates, our dedicated team is here to help you maximize the value of your investment in our WMS