Seasonal Demand Fluctuation

Seasonal demand fluctuations significantly impact standard order volumes, making it difficult for warehouses to process and fulfill orders while maintaining operational efficiency. This can be a major challenge, as swift fulfillment is crucial to retain customers. Let’s explore the challenges and importance of managing seasonal demand hikes and some general strategies for addressing them, alongside tools that can assist.

Importance of Managing Demand Fluctuations

- Competitive Advantage: Companies that can navigate these fluctuations are better equipped to respond to market changes, keeping them ahead of competitors.

- Customer Loyalty: Meeting high consumer expectations for fast, reliable deliveries even during peak seasons, boosts customer loyalty and helps businesses attract and retain buyers.

- Operational Stability: Effectively managing increased sales can minimize disruptions, helping businesses maintain productivity and avoid bottlenecks.

- Scalability: Successful demand management enables businesses to scale operations in response to changing seasons, promoting long-term growth and profitability.

- Cost Reduction: Balancing supply and labor in response to fluctuating demand helps reduce costs related to storage and workforce management.

Challenges of Managing Demand Fluctuations

- Supply Management: Predicting the right amount of stock during peak and off-peak seasons is critical. Overstocking can lead to excess storage costs, while stock-outs result in lost sales opportunities.

- Labor Allocation: Aligning labor needs with demand is difficult. Overstaffing increases costs, while understaffing can cause delays in operations, leading to inefficiencies.

- Space Optimization: Maximizing available warehouse space during seasonal demand hikes is challenging, as businesses need more storage during peak seasons but may have unused space during slower periods.

- Order Fulfillment: Rapid and accurate order fulfillment is harder to maintain during peak times due to bottlenecks in picking, packing, and delivery operations.

- Consumer Expectations: Customers expect fast, reliable deliveries year-round. Failure to meet these expectations, especially during busy seasons, can result in lost customers and negative reviews.

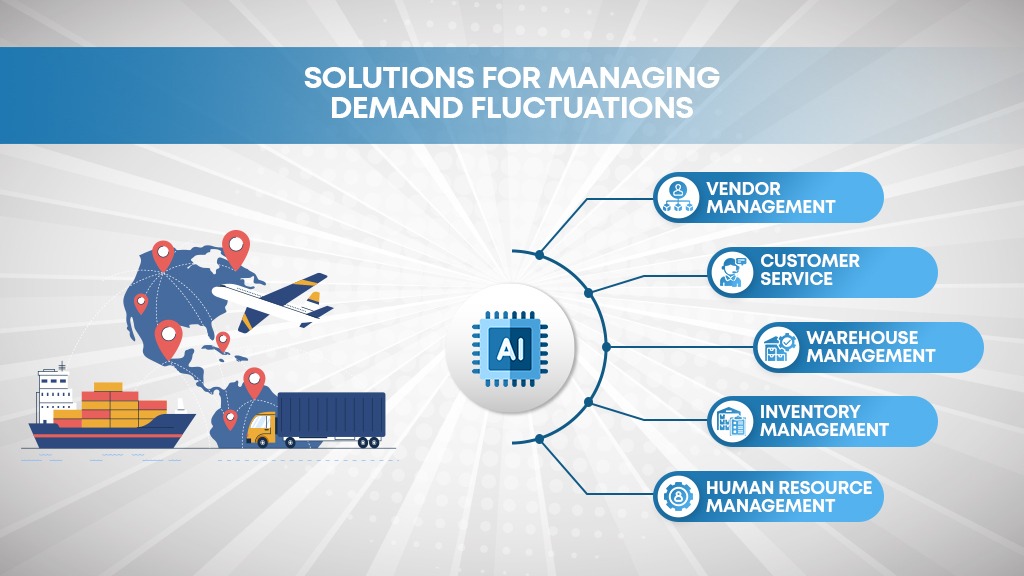

Solutions for Managing Demand Fluctuations

- Advanced Analytics: Using demand forecasting tools helps warehouse owners/managers plan labor and stock levels more accurately. This reduces the risk of overstocking or running out of products during peak periods.

- Flexible Labor Management: Identifying the right demand helps in allocating labor based on demand predictions, allowing companies to adjust staffing levels dynamically, such as scheduling part-time workers during peak times.

- Scalable Storage: Dynamic storage solutions allow businesses to adjust or fully utilize their warehouse capacity as needed, ensuring warehouses can accommodate fluctuating stock levels without underutilizing space during off-peak seasons.

- Customer Communication Tools: Maintaining clear and proactive communication with customers such as order updates, fast delivery facilities help manage expectations during high-demand periods, improving overall customer satisfaction.

- Automated Order Processing: Advanced technology tools that streamline order processing, from picking, packing to delivery, can reduce errors and speed up fulfillment, especially during high-volume periods.

Stay One Step Ahead of Seasonal Demand with 3PLNext

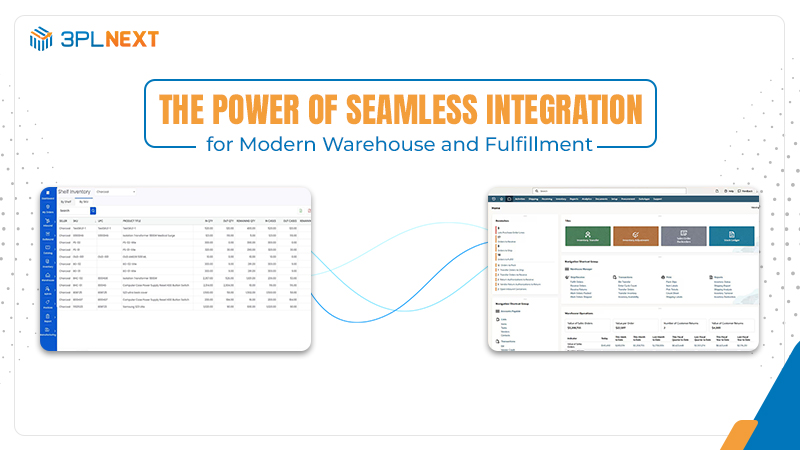

Accurate demand forecasting is crucial for navigating seasonal demand fluctuations. With 3PLNext’s advanced warehousing & fulfillment management system, you can leverage real-time data and predictive analytics to anticipate changes in demand based on historical sales trends and customer behavior. This ensures that your inventory is optimized, preventing costly stockouts or excess stock during peak seasons.

3PLNext’s system enables you to track SKU-level performance, giving you detailed insights into which items will see increased demand during specific seasons. This allows for more precise inventory planning, helping you focus on the products that matter most during key times of the year.

Additionally, 3PLNext offers real-time inventory tracking and automatic reorder point notifications, so you can maintain optimal stock levels. The system analyzes inventory turnover to predict how long stock will last and when you’ll need to restock, ensuring timely reorders without manual guesswork.

Unlike other solutions, 3PLNext’s platform integrates seamlessly with your existing warehouse operations, offering a full-service solution that includes not only demand forecasting but also streamlined inventory management, labor optimization, and order fulfillment. Plus, if you’re preparing for seasonal demand changes, you can count on 3PLNext’s flexible system to scale up your operations, eliminating the need for last-minute fixes.

Leave a Reply